From Components to Performance: The Complete Remedy for Mining Equipment Parts

From Components to Performance: The Complete Remedy for Mining Equipment Parts

Blog Article

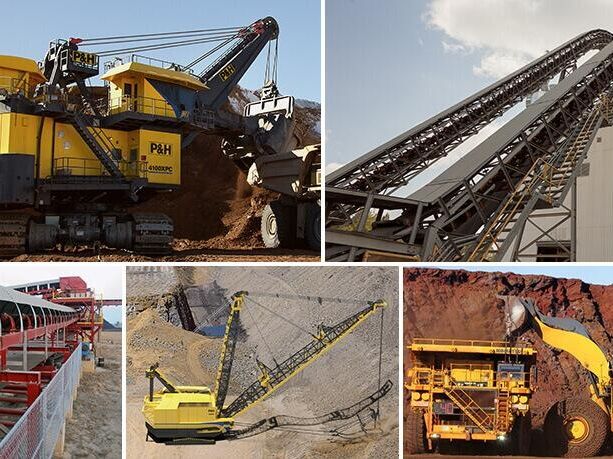

Introduction Necessary Mining Tools Components for Ideal Procedures

In the intricate globe of mining procedures, the smooth functioning of equipment is extremely important. As we dive into the depths of mining devices essentials, a better look at the elaborate details and capabilities of these components reveals a fascinating world where efficiency and integrity are the cornerstones of success.

Relevance of Appropriate Drill Little Bits

Correct selection and maintenance of drill little bits are basic for taking full advantage of mining performance and productivity (mining equipment parts). The type of drill little bit picked should align with the specific geological problems of the mining site to guarantee optimal performance.

Normal upkeep of drill little bits is similarly essential to guarantee longevity and performance. Boring or damaged drill little bits can lead to decreased drilling rate, boosted wear on drilling tools, and inevitably, reduced performance. Upkeep jobs might include honing, regrinding, or replacing worn parts to maintain the drill bits in top working condition.

Trick Elements in Conveyor Solutions

Reliable material transportation in mining procedures greatly relies on the capability and integrity of vital components in conveyor systems. One critical element is the conveyor belt itself, which brings the materials along the mining website.

Vital Filters for Tools Upkeep

An important facet of making sure the longevity and ideal performance of mining devices hinges on the careful option and maintenance of important filters. Filters play an important duty in safeguarding mining machinery from impurities that can cause damage, leading to expensive fixings and downtime. Dirt, dirt, and debris are prevalent in mining environments, making the correct filtering system necessary to tools resilience.

Filters in mining equipment serve to trap bits that could penetrate delicate parts such as hydraulics, engines, and transmissions. Routinely changing these filters according to supplier suggestions is vital to stop blocking and ensure efficient procedure. Overlooking filter maintenance can lead to decreased tools life expectancy, reduced efficiency, and boosted fuel consumption.

Essential Put On Components for Crushers

In the realm of mining tools upkeep, one essential facet that demands focus is the recognition and substitute of vital wear components for crushers. Crushers play a basic role in the link ore processing and worldly decrease procedures within mining operations. A few of the crucial wear components that are important for the efficient functioning of crushers include the complying with:

** Crusher Liners **: These are critical in protecting the crusher shell from deterioration brought on by the product being crushed.

** Jaw Plates **: Found in jaw crushers, these parts are accountable for squashing the product against a repaired surface.

** Mantles and Concaves **: These parts are crucial in gyratory crushers, where they assist in squashing the material right into an extra refined kind.

Regular inspection and replacement of these wear components are critical to ensure the crushers operate at their ideal performance, reducing downtime and taking full advantage of performance in mining procedures. Appropriate maintenance of these wear components can considerably affect the general performance and durability of the crushers, ultimately contributing to the success of mining activities.

Duty of Hydraulic Cylinders in Mining

Playing a critical duty in modern-day mining procedures, hydraulic cylinders are essential elements that promote the efficient functioning of numerous hefty machinery. These hydraulic cylinders are crucial for powering vital mining tools such as excavators, loaders, drills, and bulldozers. Among the primary features of hydraulic cylinders in mining is to supply the pressure needed to relocate hefty lots and materials in difficult terrains. The capacity of hydraulic cyndrical tubes to generate enormous power in a regulated manner makes them essential for jobs like training, pressing, pulling, and crushing within mining procedures.

Hydraulic cyndrical tubes in mining tools are created to withstand severe operating problems, consisting of severe temperature levels, high stress, and see here now hefty loads. In significance, hydraulic cylinders play an essential function in improving the performance and performance of mining operations worldwide.

Verdict

To conclude, it is vital for extracting procedures to make use of appropriate drill little bits, key components in conveyor systems, important filters for equipment upkeep, crucial wear parts for crushers, and hydraulic cylinders. These necessary mining visite site devices components play a considerable function in making certain optimal procedures and optimizing performance in the mining sector. By purchasing trustworthy and high-grade devices parts, mining companies can enhance productivity and reduce downtime, ultimately resulting in a much more effective operation.

In the intricate world of mining operations, the smooth performance of tools is paramount. By spending in premium filtration systems and sticking to a stringent upkeep schedule, mining procedures can enhance devices dependability, minimize downtime, and eventually enhance performance.

In the world of mining devices maintenance, one vital element that demands focus is the identification and substitute of essential wear components for crushers. These necessary mining equipment parts play a significant function in ensuring ideal operations and maximizing efficiency in the mining market. By investing in high-grade and reliable tools components, mining companies can improve performance and minimize downtime, eventually leading to a much more effective operation.

Report this page